The natural integration of technical calculations into the development process, including the implementation of highly expert analyzes and simulations, enables:

- reduce the number of development iterations

- reduce the cost of manufacturing and testing large numbers of prototypes,

- to shorten the development project times of our partners.

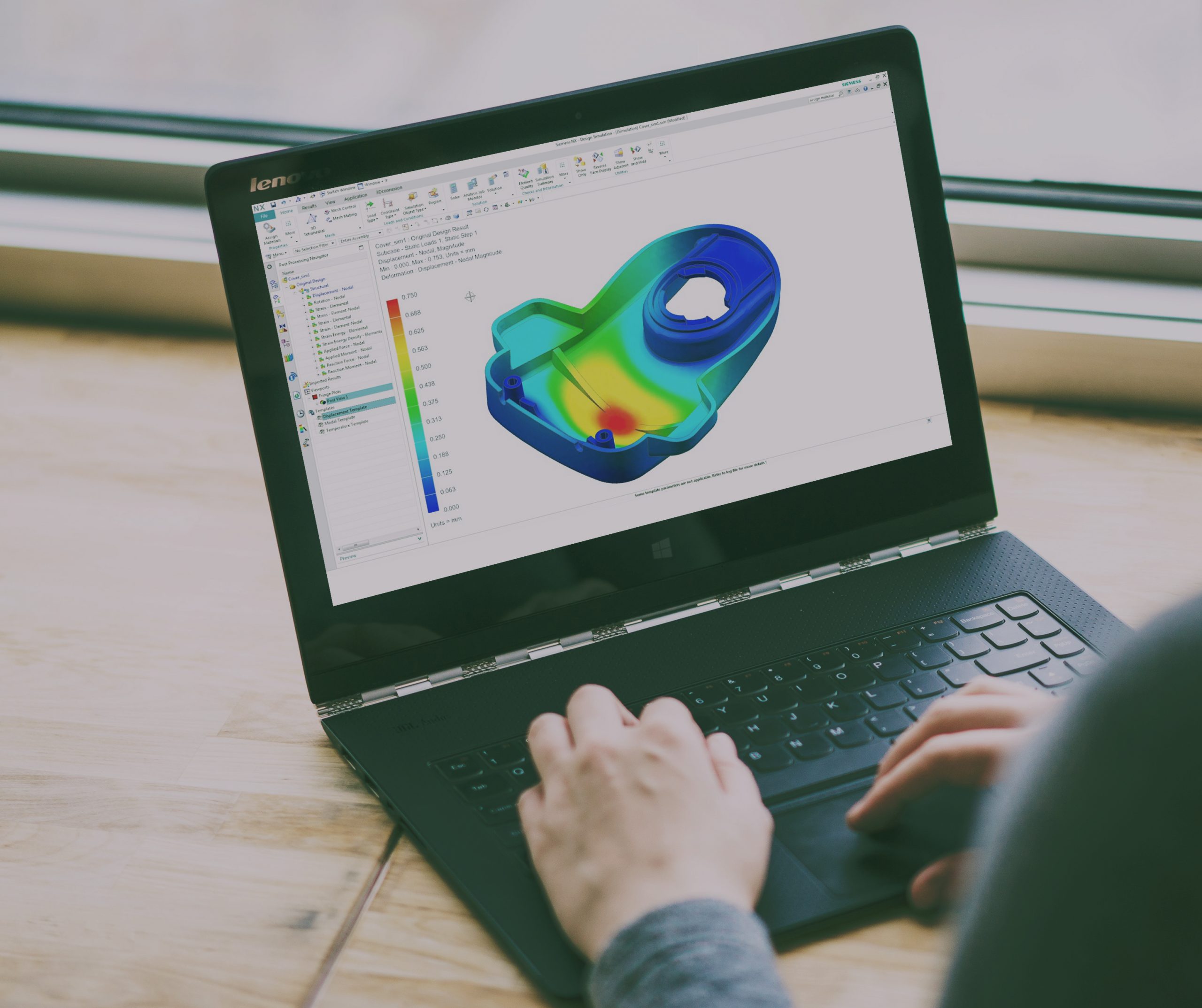

Performing stress and strain analyzes using the FEM (Finite Element Method) with detailed documentation. Upon request, optimization suggestions or strength verifications according to the FKM guideline can be carried out on the basis of the FEM analysis. For damage analysis, an existing component can also be created as a 3D model and used as a simulation model for an FEM analysis.

Strength calculations - FEM

Strength calculations using the finite element method in both linear and nonlinear regions.

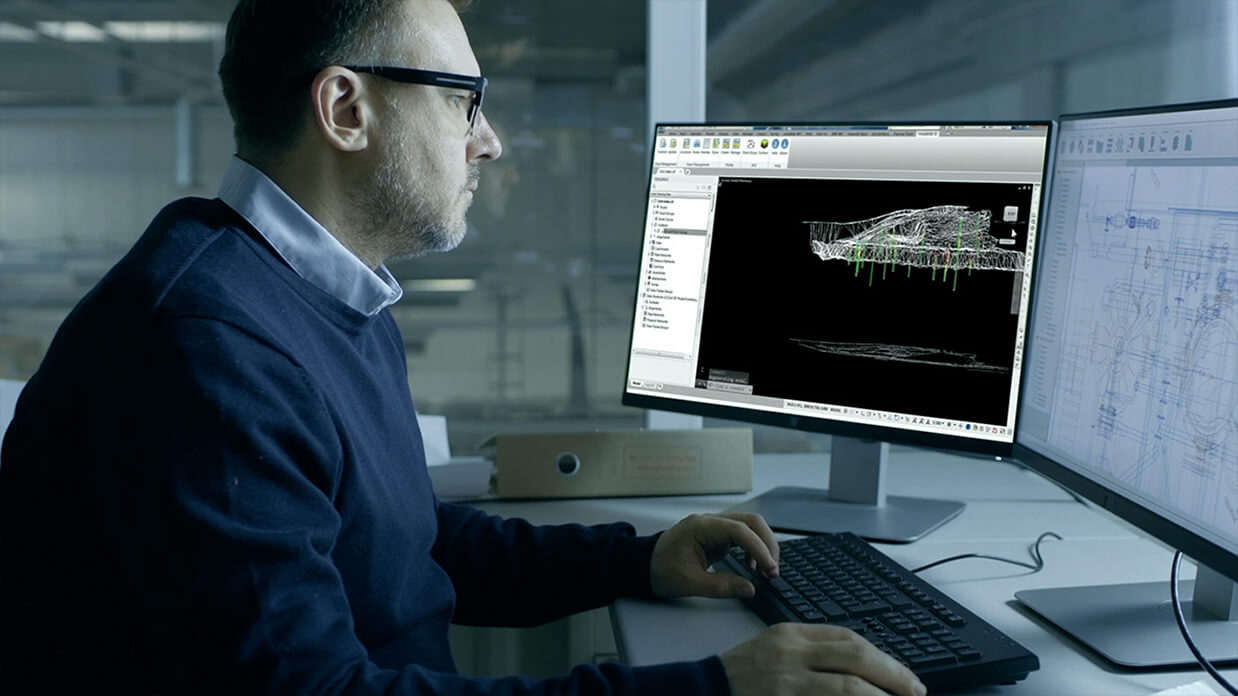

Simulation of production and assembly processes

Dimensioning of mechanical system elements, solution of contact problems, calculation of component lifetime, strength simulations using non-linear material models.

Simulation of processes in production and assembly of mainly automotive components. 3D visualization using CAD tools. Manufacturing analyzes, identification of weak points and possible collisions, layout of workplaces, production and assembly lines, planning of necessary resources, optimization of the order of individual operations, ergonomics analyzes in production and assembly processes.